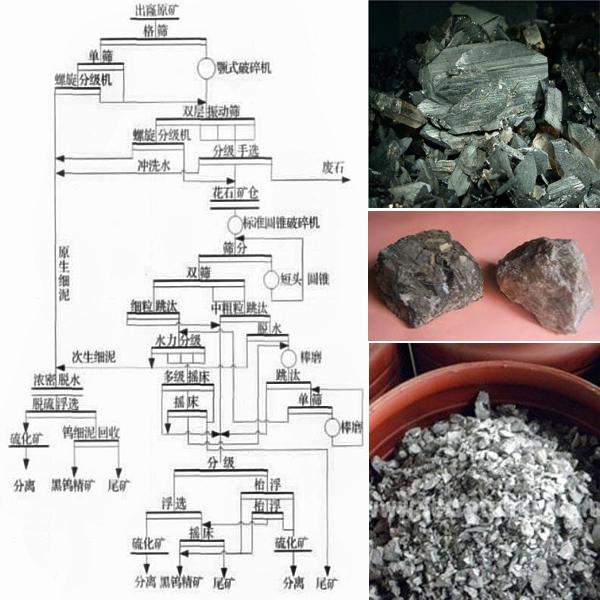

Most of the Wolframite contained by big quartz vein or fine vein wolframite , rough embedded grain ,easy to be separated . For the wolframite separation , utilize unit methods but mainly gravity concentration , divides into rough separation , gravity separation , concentrate separation and fine pulp treatment .

Application

this method is specialized in separation of the different size of grain embedded .

Roughing

In the stage of roughing, Jinpeng provides a method for the wolframite beneficiation plant. That is using vibrating screen jig in the first stage of fine slime, then going directly to the process of cleaning.

In this stage, Jinpeng would always apply the processing of multistage jig, multistage shaking table and regrind of middling. That is, after the stage of fine crushing, the qualified mineral will be classified by vibrating screen and then put into the multistage jig. After that the jig gravity rough concentrate is produced. The coarse jig tailings will be reground. The fine jig tailings will be classified by classifier and then put into multistage shaking table. After that the shaking table gravity rough concentrate is produced. The tailings will be discharged into tailings pond. The mineral left on the table will be reground and concentrated. The gravity sand concentrated by jig and shaking table will be concentrated in the process of cleaning.

Cleaning

In this stage, Jinpeng would always apply the processing of flotation-gravity technology or flotation-gravity-magnetic technology, at the same time recycle the accompanying element. In this stage, by using the process of table flotation of coarse and fine particle fractions (combination of flotation and shaking table) and flotation, sulphide ores will be removed. Then the sulphide ore will put to sulfide flotation, and wolframite ore will be further concentrated through gravity sepatation. If the wolframite concentrate contains scheelite and cassiterite, the process of flotation-gravity technology or flotation-gravity-magnetic technology should be applied to separate out wolframite concentrate, scheelite concentrate and cassiterite concentrate.

Slime Treatment

Common practice of slime treatment in Jinpeng is as follows. At first, sulfur removal. Then according to the material property to select separation technology to recycle tungsten, such as gravity separation, floatation, magnetic separation, electric separation, etc or combination of several process. At the same time, comprehensive utilization of associated metal minerals.