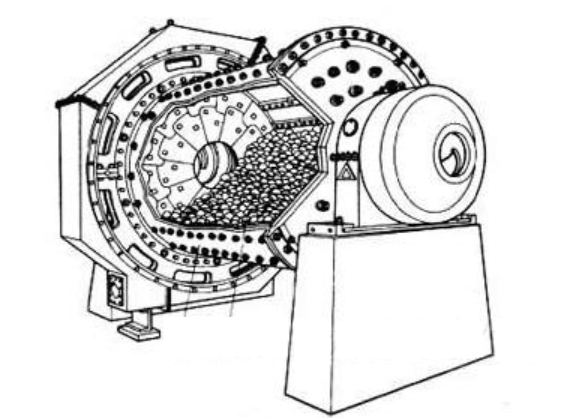

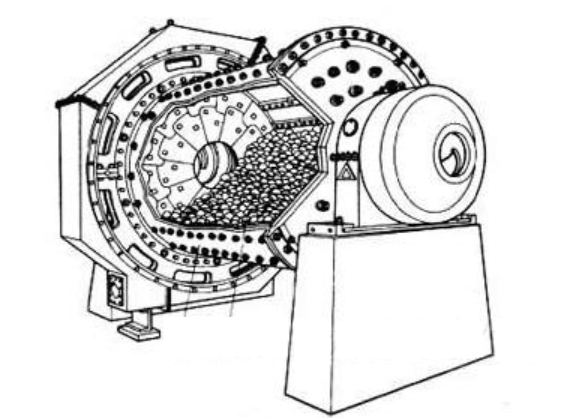

Structure

Ball mill is mainly composed of feeding, feeding, main bearing, cylinder, transmission department, delivery department and the main motor and other parts.

Production capacity : 0.62-180t/h

Scope of Application : Cement, Portland products, new building material, refractory material, fertilizer, black and non-ferrous metal processing, glass ceramics production industry,dry grinding,ect

Ball mill is mainly composed of feeding, feeding, main bearing, cylinder, transmission department, delivery department and the main motor and other parts.

1. Save energy: bush bearing is replaced by rolling bearing, friction resistance being greatly lowered down, easy to be started. It’s energy is lower 10-15% than the old one.

2. Large capacity: for the outlet disk and the checked liner are adopted, the capacity is higher 20% than the cone ball mill.

3. The discharging port slurry surface is low, slurry flow through rapidly, decrease ore over-grinding.

4. Load of ball is large, big balls, small balls be loaded in, and small balls can’t be discharged, and can form good working conditions.

| Dry ball mills | ||||||||||

Model | specification | barrel | Motor | Production capacity(t/h) | Effective volume(m³) | Max loading ball(t) | Note | Weight(kg) | ||

length(mm) | speed(r/min) | Model | Power(kw) | |||||||

MQG0909 | 900 | 900 | 37.1 | Y200L-8 | 15 | 0.16-0.8 | 0.45 | 0.96 | single silo | 4.4 |

MQG0918 | 900 | 1800 | 37.1 | Y225L-8 | 22 | 0.33-1.6 | 0.9 | 1.92 | single silo | 5.7 |

MQG1212 | 1200 | 1200 | 33.4 | Y250L-8 | 30 | 0.16-2.4 | 1.1 | 2.4 | single silo | 10.5 |

MQG1224 | 1200 | 2400 | 33.4 | YR280S-8 | 55 | 0.3-2.8 | 2.2 | 3.96 | single silo | 12.5 |

MQG1228 | 1200 | 2800 | 33.8 | YR280S-8 | 55 | 0.3-3.0 | 2.8 | 5 | single silo | 13.6 |

MQG1515 | 1500 | 1500 | 30.9 | JR115-8 | 60 | 1.0-3.0 | 2.2 | 5 | single silo | 14 |

MQG1530 | 1500 | 3000 | 30.9 | JR125-8 | 95 | 1.5-3.5 | 4.4 | 8.6 | single silo | 19 |

MQG1530 | 1500 | 3000 | 30.9 | JR125-8 | 95 | 1.5-3.5 | 4.4 | 8.6 | single silo | 19.5 |

MQG1557 | 1500 | 5700 | 30.9 | JR127-8 | 130 | 2.0-4.5 | 8.6 | 14.5 | single silo | 26.5 |

MQG1557 | 1500 | 5700 | 30.9 | JR127-8 | 130 | 2.0-4.5 | 8.6 | 14.5 | double silo | 26.8 |

MQG1836 | 1800 | 3600 | 25.2 | JR128-8 | 155 | 2.0-5.0 | 7.5 | 13.5 | single silo | 34.1 |

MQG1840 | 1800 | 4000 | 25.2 | JR128-8 | 155 | 2.0-5.0 | 8.2 | 14.5 | single silo | 36.4 |

MQG1860 | 1800 | 6000 | 25.8 | JR138-8 | 245 | 5.5-9.0 | 12.6 | 22.5 | double silo | 44 |

MQG1870 | 1800 | 7000 | 25.8 | JR138-8 | 245 | 6.0-10.5 | 13.6 | 24.5 | double silo | 47.5 |

MQG2130 | 2100 | 3000 | 24.05 | JR136-8 | 180 | 4.5-5.5 | 6.6 | 16 | single silo | 49 |

MQG2136 | 2100 | 3600 | 24.05 | JR137-8 | 210 | 4.5-6.5 | 11 | 21 | single silo | 54 |

MQG2445 | 2400 | 4500 | 22.5 | JR500L3-8 | 380 | 8.0-12 | 17.3 | 33 | single silo | 71 |

MQG2745 | 2700 | 4500 | 61.6 | TDMK500-32/2150 | 500 | 1.0-16.0 | 23 | 42 | single silo | 109 |